The Research Team of Professor Zhao Yuanjin Made Great Progress in the Development of Cardiac Chip

Recently, the research team led by Professor Zhao Yuanjin from Department of Biological Science and Medical Engineering, SEU, made significant pr·ogress in cardiac chip research. They developed a series of bionic helical fibers based on microfluidic technology, and used it as a microspring to indicate the contraction force of cardiomyocytes. The research paper was published in the internationally renowned academic journal Advanced Materials (impact foctor: 18.96) in March 7, 2017. The first author of the paper was Yu Yunru, doctoral student of 2016. Professor Zhao Yuanjin was the only corresponding author. Their research has been funded by the National Fund Committee and the 111 program, which is also called Southeast University Organ Chip Innovation Base Project. It was also the sixth paper that Professor Zhao Yuanjin published in this journal as the first author or corresponding author, with Southeast University as the first unit.

The organ chip, which is to build biomimetic micro-organs on chips to replace the organism, is used for drug evaluation and biological research. The construction of cardiac chip with myocardial cell mechnics is an important part of organ chip development. The research team proposed to use a helical fiber structure as mechanical sensors for cardiomyocytes. The helical structure, which is the best existence form in a limited space, is one of the most common forms in nature. It is represented in the storage of genetic information -- DNA, plant vines climbing in other objects and the spring. Inspired by this, scientists have developed a series of helical fibers for microelectromechanical systems (MEMS), optical sensing, and etc. However, due to the limitations of the means of preparation, the reports about biomimetic helical microfibers, especially biologically responsive ones, are zero.

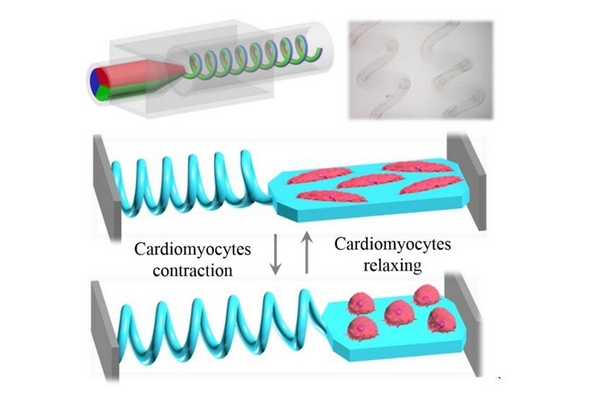

The research team found they could get microfibers with continuous helical structure through controlling the flow of multi-phase fluid in microchannels and combining it with the fast gelation process. Thus, by taking advantage of the microfluidic technology and widening microfluidic channels, the resultant helical microfibers were imparted with structures such as Janus, triplex, core-shell and even double-helix. Because of the flexibility of the hydrogel material the makes up the fibers, the helical fibers may have different stimulus response, which is characterized by the reusable change - basic properties of the spring, by incorporating magnetic and temperature responsively objects. Based on this, the researchers connected the helical fibers to hydrogel membrances with cardiomyocytes of mouses (as shown in the figure) and they found that the frequency of the transformation cycle of the helical microfiber corresponded to the beating frequency of the cardiomyocytes. By measuring the elastic modulus of the fibers, they could calculate the contraction force of cardiomyocytes on the membrane, thus the helical microfibers could serve as a force indicator for the contraction of cardiomyocytes. This technique has important application value in the drug development of cardiomyocytes.